Learn more about Greek yogurt

Greek yogurt is made by removing whey, a liquid that can cause several environmental impacts

Myriam Zilles image by Pixabay

A source of vitamins, calcium and proteins, yogurt is an important component of our daily diet. It is the result of the fermentation of milk by bacteria, which are called probiotics and are responsible for the digestibility of the food. Having this step as a common point in the manufacture of all types and flavors of yogurt, the differences between Greek yogurt and common yogurt begin to appear in the next stage of production.

What is Greek yogurt?

Traditionally, Greek yogurt is made by removing the whey, the liquid remaining after the milk has curdled. The end result of this process is a more solid yoghurt, with less sugar and carbohydrates and more protein compared to regular yoghurt. According to nutritionist Tatiana Hirooka, Greek yogurt is considered an intermediate product between traditional fermented milk and non-matured cheeses with high moisture content, such as boursin, quark or petit suisse.

Greek yogurt making

The manufacture of Greek yogurt varies by manufacturer. It can be produced by an industrial process, which removes whey, or by adding milk proteins, cream or natural thickening gums. These Greek yoghurt production methods are responsible for the food's much appreciated creaminess, capable of conquering even the most demanding consumer. But this type of yogurt, despite having more protein and calcium, also has more calories and fat.

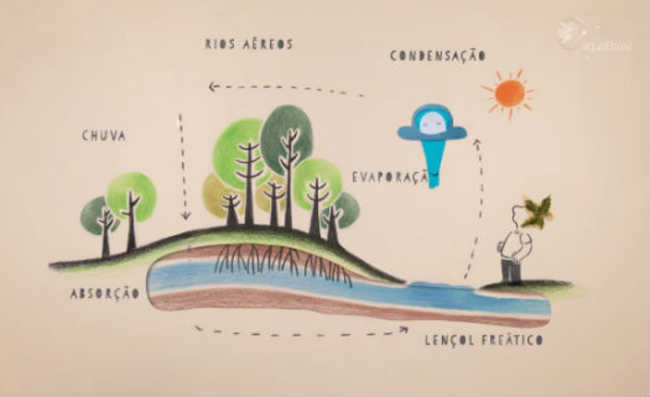

The main residue generated by industrial production, whey does not have its market value recognized in Brazil, and ends up being dumped in water courses, causing pollution. Serum has a high biochemical oxygen demand, that is, it needs a large amount of oxygen in the environment to be degraded. Thus, the whey from the manufacture of Greek yogurt compromises the level of oxygen present in the water, causing the death of plants and animals that depend on this element to survive.

Alternatives for the disposal of the effluent generated in the production of Greek yogurt

Taking into account the nutritional value of the whey generated in the production of Greek yogurt, as well as the high cost of treating this effluent, other alternatives have emerged to prevent the environmental impacts caused by the incorrect disposal of the liquid in watercourses.

In order not to dump the whey produced in watercourses, many producers have returned the whey to the farms. Thus, it is added to the feed of animals and supplements the load of protein and energy needed by them daily. In addition, the whey could be used for the manufacture of breads, sweets, ricotta cheese, concentrated juices and also in the extraction of yeasts.

In the United States, a large Greek yogurt company has given its waste another type of destination. It sends the whey produced to a wastewater treatment plant, which puts all the contents received into an anaerobic biodigester. In this large tank, composed of bacteria that work in the absence of oxygen, methane gas is produced. This biogas will serve as a source for energy generation, which is capable of feeding, for example, the yogurt factory itself. This is a smart and cost-effective way to treat the generated whey.

Source: Greek Yogurt