Know the types of plastics

Associate the type of plastic to your day-to-day products and learn how to properly dispose of it

Plastic is one of the most common materials in our daily lives. The various types of plastic serve as raw material for the manufacture of toothbrushes, toys, jewelry, computer parts, kitchen utensils, among others. Its use in a wide range of products is due to factors such as high durability, low energy consumption and ease of transport and processing.

They are basically divided into thermoplastics and thermosets, being, respectively, recyclable and non-recyclable at high temperatures. The categorization divides plastics into seven types:

- PET or PETE (Polyethylene Terephthalate)

- HDPE (High Density Polyethylene)

- PVC (Poly Vinyl Chloride or Vinyl Chloride)

- LDPE (Low Density Polyethylene)

- PP (Polypropylene)

- PS (Polystyrene)

- other plastics

Whether recyclable or not, the incorrect disposal of plastic can be very harmful to the environment and human health, as, when escaping, it can contaminate the environment and enter the food chain. Therefore, care must be taken not to let the plastic end up in the environment, whether by reusing it, disposing of it for recycling (when it is recyclable) or to landfills (when it is not possible to recycle it).

- There are microplastics in salt, food, air and water

- Understand the environmental impact of plastic waste on the food chain

How do I identify the type of plastic I purchased?

For consumers to know which type of plastic the product they are buying is made from, there is a standard used by factories. You may have noticed that there are numbers surrounded by a triangle with arrows on the labels of the plastic products you buy. They have the function of alerting consumers about selective disposal, in addition to guiding the proper separation of each material.

In Brazil, the technical standard for plastic (NBR 13.230:2008) was conceived in accordance with international criteria. The numbering separates the material into six different types of plastics (PET, HDPE, PVC, LDPE, PP, PS) and there is also a seventh option (others), normally used for plastic products made with a combination of different resins and materials . Check out the picture below:- PET or PETE (Polyethylene Terephthalate)

- HDPE (High Density Polyethylene)

- PVC (Poly Vinyl Chloride or Vinyl Chloride)

- LDPE (Low Density Polyethylene)

- PP (Polypropylene)

- PS (Polystyrene)

- other plastics

"Water Bottle" by Juan Manuel Corredor, "plastic bag" by Gilda Martini, "pipe" by Bakunetsu Kaito, "plastic cup" by Juraj Sedlák, "sponge" by Vittorio Maria Vecchi, "plastic wrap" by S. Salinas and " Plastic Deck Chairs Sun Beds" by Oleksandr Panasovskyi in the Noun Project

The problem is that, in Brazil, a significant portion of plastic objects are not identified or are misidentified.

Thermoplastics, thermosets and recycling

Thermoplastics are a type of synthetic plastic that can be heated without changing its chemical properties. This is very advantageous for recycling as the material can be molded into other shapes and therefore recycled. As such, all thermoplastics are potentially recyclable.

Below is a sequence of types of plastics that fall into the thermoplastics category:

PET: poly (ethylene terephthalate)

Bbxxayay, Bottle-pet-green, CC BY-SA 4.0

Polyethylene terephthalate, or PET, is a type of plastic formed by the reaction between terephthalic acid and ethylene glycol. PET plastic normally comprises bottles and bottles for food/hospital use, cosmetics, microwave trays, films for audio and video and textile fibers. It is a material widely used because it is transparent, unbreakable, waterproof and light. As it is a thermoplastic, PET is recyclable. The downside is that PET is made from petroleum - a non-renewable source - and, when mixed with other types of materials, such as cotton fibers - in the case of PET clothes - its recycling becomes impossible.

HDPE: high density polyethylene

High-density polyethylene, or HDPE, is present in detergent and automotive oil packaging, supermarket bags, wine cellars, lids, paint drums, pots, housewares, among others. It is a plastic material widely used because it is unbreakable, resistant to low temperatures, light, waterproof, rigid and chemically resistant. As it is a thermoplastic, HDPE is recyclable. It can be obtained from petroleum or plant sources, when the latter occurs it is called green plastic.

Frank Habel image by Pixabay

PVC

seo24mx image in Pixabay

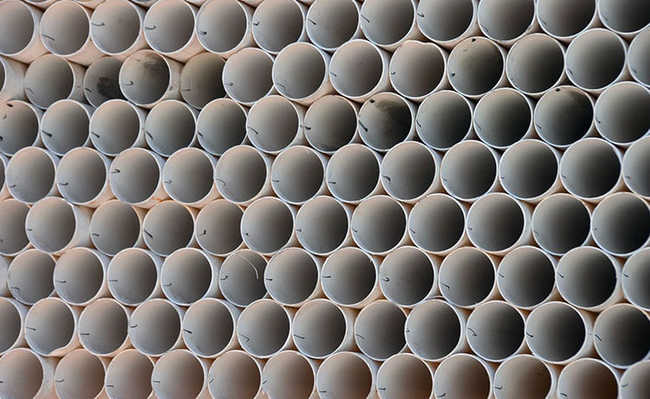

PVC plastic, or better said, polyvinyl chloride, is a type of plastic commonly found in packaging for mineral water, edible oils, mayonnaise, juices, window profiles, water and sewage pipes, hoses, packaging for medicines, toys, blood bags, hospital supplies, among others. It is widely used because it is rigid, transparent (if desired), waterproof, temperature resistant and unbreakable.

PVC is made up of 57% chlorine (derived from a salt of the same type as table salt) and 43% ethylene (derived from petroleum). In Brazil, the PVC recycling rate has grown over time. The reuse of material, when well separated, can be done in a simple and less costly way. However, one downside is that it contains dioxin, a substance that accumulates in the body and can cause cancer. Learn more about this topic in the article: "Dioxin: know its dangers and be on the safe side". Depending on the final application, plasticizers, stabilizers and others can be added. Learn more about it in the article "PVC: uses and environmental impacts".

LDPE or LLDPE

ToddTrumble image by Pixabay

Low-density polyethylene, or LDPE, is present in bags for supermarkets and boutiques; films for packaging milk and other foods; industrial sacks; disposable diaper films; bag for medical serum; garbage bags, among others. It is a type of plastic widely used because it is flexible, light, transparent and waterproof. As a thermoplastic, LDPE is recyclable. It can be obtained from petroleum or plant sources, when the latter occurs, as well as the already mentioned HDPE, it is called green plastic.

PP: polypropylene

This type of plastic has the characteristics of preserving the aroma, being unbreakable, transparent, shiny, rigid and resistant to temperature changes. It is widely used in films for packaging and food, industrial packaging, ropes, hot water pipes, wires and cables, bottles, beverage boxes, auto parts, fibers for carpets and housewares, pots, diapers and disposable syringes, etc.

It is a thermoplastic derived from propene (recyclable plastic). It has properties similar to polyethylene, but with a higher softening point.

PP has a variation called BOPP, a metallized plastic that is difficult to recycle, common in snack and cookie packaging. Read more about it in "BOPP: is plastic that wraps sweets and snacks recycled?".

Image of kalhh by Pixabay

PS: polystyrene

Image of Félix Juan Gerónimo Beltré by Pixabay

Polystyrene, used in yogurt pots, ice cream, candy, jars, supermarket trays, refrigerators (inside the door), plates, lids, disposable cups, disposable razors and toys is a resin from the thermoplastics group. In addition to being recyclable, polystyrene has characteristics such as lightness, thermal insulation capacity, low cost, flexibility, and moldability under the action of heat, which leaves it in a liquid or paste form.

PLA plastic

PLA: poly (lactic acid)

PLA plastic is produced from lactic acid obtained from the fermentation of starch from beetroot, cassava and other vegetables. It is compostable, biodegradable, recyclable (mechanically and chemically), biocompatible and bioabsorbable. PLA plastic can be used in cups, containers, food packaging, bags, disposable plates, bottles, pens, trays, 3D printer filaments and others. The problem is that, as in the case of 3D printer filaments, it ends up being mixed with other types of plastics, which makes its recycling unfeasible. To learn more about PLA plastic, check out the article: "PLA: biodegradable and compostable plastic".

Sascha_LB image in Pixabay

Thermoset

Thermosets, thermosets or thermosets are plastics that do not melt even at high temperatures. On the contrary, at high temperatures these materials decompose, which makes recycling impossible. Thus, thermoset plastic is difficult to recycle.

Check out a sequence of thermoset materials below:

PU: polyurethane

Capri23auto image in Pixabay

Flexibility, lightness, abrasion resistance, possibility of design differentiated are its main positive characteristics. The application is in soft foams for mattresses and upholstery, rigid foams, shoe soles, switches, electrical industrial parts, surfboards, bathroom parts, dishes, sleepers, ashtrays, telephones, etc. The biggest problem with polyurethane is that it is still difficult to recycle.

Like all plastics, polyurethane is a polymer made from the reaction of two main substances: a polyol and a di-isocyanate. The raw materials used in the process can vary according to the application's needs. In terms of polyols, the most used are castor oil and polybutadiene. Among the di-isocyanates, the “famous” diphenylmethane di-isocyanate (MDI) and hexamethylene di-isocyanate (HDI) stand out, among other complicated names.

In the case of kitchen sponges, the most viable solution is to replace them with vegetable sponge. To know what to do with the polyurethane kitchen sponge, check out the article: "What to do with the kitchen sponge?" To learn more about polyurethane, take a look at the article: "What is polyurethane?"

EVA: ethylene vinyl acetate

Iva Balk image in Pixabay

The main characteristic of EVA, ethylene vinyl acetate, is the ability to be flexible and resistant at the same time. As the name implies, it is made from a high-tech blend of ethyl, vinyl and acetate, and is commonly used as shoe soles and slippers, in gym equipment, toys, craft supplies and more. Like polyurethane, the problem with EVA is that it is difficult to recycle.

Bakelite

Pxhere CC0

Bakelite is, chemically speaking, polyoxybenzylmethylenglycolanhydride. It is formed by joining phenol with formaldehyde, which gives rise to a polymer called polyphenol. It is a heat resistant, infusible, strong synthetic resin that can be molded early in manufacture. Furthermore, Bakelite is inexpensive and can be incorporated into varnishes and lacquers. The application takes place in pot cables, radio components, telephones, switches, lamp sockets, etc.

- What to do with varnish?

Bakelite is rarely used. Old bakelite products are often collectibles and are difficult to recycle.

phenolic resin

Adriano Gadini image by Pixabay

Phenolic resins are thermoset polymers, or thermosets, produced through chemical condensation reactions between a phenol (aromatic alcohol derived from benzene), or a phenol derivative, and an aldehyde, especially formaldehyde. Phenolic resins have good thermal behavior, high level of strength and resistance, long thermal and mechanical stability, good ability to act as electrical and thermal insulator.

This type of resin is widely used in pool balls, coatings, adhesives, paints and varnishes. Unfortunately it is not recyclable. But just like any type of plastic, it also requires a correct disposal so that it does not contaminate the environment.

Stay tuned

Oxidegradable

Oxidegradable plastic, also called "oxybiodegradable", is based on polyethylene (PE), polypropylene (PP), polystyrene (PS) and polyethylene terephthalate (PET), thermoplastics already mentioned. But what determines its oxidegradability condition (degradation by oxygen) is that pro-degrading additives are used, which have the property of fragmenting the plastic, facilitating decomposition. This type of plastic has a controversial use, mainly in relation to the feasibility of recycling it and the waste generated, such as microplastic. To understand this issue in more detail, check out the article: "Oxo-biodegradable plastic: environmental problem or solution?".

Bisphenols

Bisphenols are not really a type of plastic in themselves, but they are substances present in some types of plastics. They are used as coatings for packaging, utensils, machinery, floors and other objects to increase the strength and durability of the material. The problem with these substances is that they cause a series of damages to human and animal organisms.

Bisphenols are endocrine disruptors present in food packaging, makeup, hygiene products, receipts, newspapers, etc. They end up migrating from the packaging to food and skin through contact and end up in the human bloodstream, causing problems in the thyroid, ovaries, testicles, among others (serious problems, such as cancer, can be stimulated by endocrine disruptors). When plastic containing bisphenol is improperly disposed of, bisphenols contaminate the water, soil and atmosphere, harming the reproduction of dolphins, whales, deer, and other animals.

To learn more about this topic, check out our article "BPS and BPF: alternatives to BPA are just as dangerous. Understand". To know the types of pollution, take a look at the article: "Pollution: what it is and what types exist".

correct destination, effectively

As you may already know, it is very important that we differentiate between recyclable and non-recyclable plastics, mainly to avoid consuming non-recyclable ones and destining recyclable ones for recycling.

It would be very complicated to banish this kind of material completely from our daily lives. But we must avoid them - especially those whose recyclability is not economically, physically or chemically viable, as is the case with BOPP plastic - preferring to consume, instead of these, recyclable products, made of glass (safer, as they do not contain disruptors endocrine) or aluminum.

It's also important to know if the item you've purchased with good intentions is actually recyclable. Example: t-shirts made with recycled PET may contain in their composition a mixture with cotton fibers, which makes new recycling unfeasible, not to mention that washing clothes containing synthetic textile fibers is responsible for releasing microplastics into the water.

- Study reveals that washing clothes made with synthetic fibers release microplastics

But it is not enough to consume recyclables instead of non-recyclables, it is necessary to guarantee recycling. Not all recyclable material ends up being recycled.To increase the chance of recycling plastic, it is necessary to pack it correctly and send it to collection and recycling stations or to the city hall.

Next, it is necessary to put pressure on governments, manufacturing companies and other consumers to guarantee recycling, since, by law, it is established that everyone is responsible for waste management.

So, after correctly disposing of your recyclable waste, call your city's municipal government, show interest in knowing if the selected garbage collected is actually being recycled. Look for the SAC of the company of the plastic product you consumed and cover the guarantee of recycling of the materials sold, remembering that the National Solid Waste Policy (PNRS) establishes that the companies are also responsible for the return of waste in the chain.

To get even more connected, check out the article: "Do you know what recycling is? And how did it come about?".

If you want to correctly dispose of your materials from different types of plastics and make your footprint lighter, consult the disposal stations closest to your home.