What are biodegradable products?

Are biodegradable products the solution to the garbage issue in cities?

Scott Van Hoy image available on Unsplash

Biodegradable packaging has been identified as a solution for the environmental impacts caused by the generation of waste. There are many existing solutions to reduce the volume of waste generated in large cities, such as recycling, composting, incineration, reuse of packaging (refillable, returnable, among others) and the use of controversial biodegradable products - a term that has been widely used in several items, as it adds an “ecologically correct” value and attracts more consumers.

- What is compost and how to make it

Biodegradation is defined as the chemical transformation process promoted by the action of microorganisms under appropriate conditions of temperature, humidity, light, oxygen and nutrients. Biodegradation can be aerobic or anaerobic. In this process, the original material is altered and, in general, transformed into smaller molecules - in some cases, water, CO2 and biomass. A very important parameter that defines whether a material is biodegradable or not is the time it takes to be decomposed by the action of microorganisms. Typically, a material is considered to be biodegradable when it decomposes over a time scale of weeks or months. For the degradation of a biodegradable material to be effective, the material must be taken, together with organic waste, to a composting unit, because, in this environment, the material will find optimal conditions to decompose.

- What is Biodegradation?

A material can even be decomposed by microbial action, but the time for this to occur is very long, thus, this material is not classified as biodegradable. For example: some types of plastics (PVC, polyethylene and polypropylene), which can be decomposed by microbial action, but take ten to 20 years to disappear - depending on their thickness, this time can be even longer - thus, they are not classified as biodegradable.

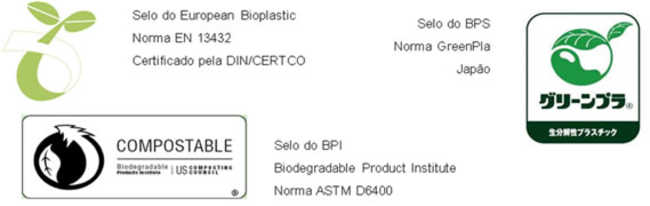

To be considered biodegradable, a material or product must meet some international standards, such as the US ASTM 6400, 6868, 6866, the European EN 13432, or the Brazilian ABNT NBr 15448 for biodegradation and composting, and prove its properties through tests in certified laboratories. Next, the steps of biodegradable (compostable) certification for a plastic and their respective standards are presented:- Chemical characterization of the material: this step includes analysis of heavy metals and volatile solids in the material composition.

- Biodegradation: it is measured through the relation between the amount of CO2 emitted by the compostable plastic with the amount emitted by a standard sample, during its biodegradation, after a period of time (ASTM D5338).

- Disintegration: the material must physically disintegrate (more than 90%) into pieces smaller than 2 mm in 90 days (ISO 16929 and ISO 20200).

- Ecotoxicity: it is verified that no toxic material, which would hinder the development of plants, can be generated during the process.

A material that has been replaced by a biodegradable variant is petroleum-derived plastic. The main reason for this is the high resistance that this material has to degradation, and some types of plastic take more than 100 years to degrade. Thus, the accumulation of material in garbage dumps and natural environments is increasing. Biodegradable plastics are classified, in a simple way, as natural or synthetic.

Synthetic Biodegradable Plastics

In this group are some types of synthetic polymers that are naturally degraded, or by the addition of substances that can accelerate their degradation. Among these plastics, oxy-biodegradables and poly(ε-caprolactone) (PCL) stand out. Oxo-biodegradable plastics are synthetic plastics in which pro-oxidant chemical additives have been incorporated into their composition, capable of initiating or accelerating the oxidative degradation process, generating products that are biodegradable. PCL is a biodegradable thermoplastic polyester that is biocompatible with medical applications.

- Oxo-biodegradable plastic: environmental problem or solution?

Natural Biodegradable Plastics

Natural biodegradable polymers, also called biopolymers, are all those produced from natural and renewable resources. They comprise polysaccharides produced by plants (corn starch, cassava, among others), polyesters produced by microorganisms (mainly by different types of bacteria), natural rubbers, among others.

Detergents

However, plastics are not the first products to undergo changes or replacement due to their environmental impact. Until 1965, detergents were used as a branched alkylated raw material (surfactant - by definition, a surfactant is a synthetic substance used in the manufacture of cleaning and cosmetic products and which causes the junction of substances that, in their natural state, would not be (such as water and oil), whose little biodegradation generated a phenomenon of foam production in watercourses and treatment plants. Thus, branched alkylates were replaced by linear alkylates, classified as biodegradable - then laws were created that prohibited the use of branched alkylates. In Brazil, the Ministry of Health prohibited, as of January 1981 (Art. 68 of Decree No. 79,094, revoked by Decree No. 8.077, of 2013), the manufacture, sale or import of sanitizers of any nature (detergents) containing non-biodegradable anionic surfactant.

The biodegradation of linear surfactants can be divided into primary and total (or mineralization).

Primary Biodegradation

Primary biodegradation is that which occurs when the molecule has been oxidized or altered by the action of a bacterium, in such a way that it has lost its surfactant characteristics or that it no longer responds to specific analytical procedures for detecting the original surfactant. This process is done quickly in most cases, several specialized bacteria are able to metabolize surfactants. Initially, primary biodegradation was accepted as sufficient, however, organic waste is considered foreign to the environment.

Total biodegradation or mineralization

Total biodegradation, or mineralization, is defined as the complete conversion of the surfactant molecule into CO2, H2O, inorganic salts and products associated with the normal metabolic process of the bacteria.

Is Biodegradation the Salvation?

With the increasing demand for biodegradable products, new product alternatives appear on the market. There is a growing number of researches for the development of conventional products, such as diapers, cups, pens, kitchen utensils, clothes, among others, in their biodegradable versions.

- First national biodegradable diaper, Herbia Baby has a smaller environmental footprint and is healthier for the baby

Despite the advantages proposed by biodegradable packaging, some researchers consider that this is not the best alternative for some types of waste. According to Professor Dr. José Carlos Pinto, from the Federal University of Rio de Janeiro (UFRJ), ecologists are wrong when they treat plastic material as garbage. For the researcher, the residue must be treated as raw material. All plastic material is potentially recyclable and reusable. For José Carlos, the State Environmental Secretariats should fight, therefore, for the popularization of environmental education and for the implementation of public policies for selective collection and recycling of garbage; in addition, the federal government should implement policies that oblige large plastics producers to invest in recycling and reusing their products.

It is important to realize that, if plastic material were to degrade, such as food and organic waste, the material resulting from degradation (for example, methane and carbon dioxide) would end up in the atmosphere and aquifers, greatly contributing to global warming and with the degradation of water and soil quality.

The biodegradation characteristic of a material can be very advantageous for the environment, but this is not the only solution to reducing waste generation. It is necessary to study all the effects that the degradation of a given material can cause to the environment, and, furthermore, consider what is the most effective destination for a given product.