Is Tetra Pak packaging recyclable?

Recycling long life packaging can be difficult, but it is possible.

Tetra Pak is the name of a prominent company that produces food packaging, being the world's largest supplier of carton packaging for milk cartons (of animal and vegetable origin), soups, juices and other liquid food products.

Although Tetra Pak is the name of the brand, in informal language, the term "Tetra Pak packaging" has become synonymous with "carton packaging", "milk carton" or "long life packaging".

It is increasingly common for products such as tomato paste, sour cream, juices, coconut water and tea to be coated with the same material, which leads manufacturers such as Tetra Pak or SIG Combibloc to develop new sizes and shapes for the boxes.

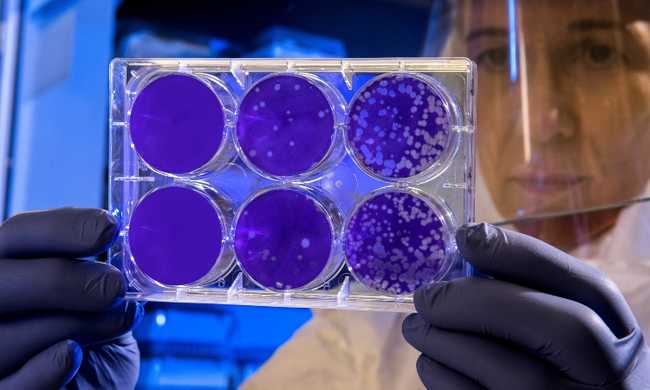

Long-life packaging, also called carton packaging, has multiple layers and varies according to the type of food – the milk carton, for example, needs six layers. These layers go through a compression process on all the sheets of the different constituents.

The composition of the long-life package is basically:- 75% paperboard - two papers joined without glue, which offer mechanical support and resistance to packaging;

- 20% polyethylene films (LDPE): prevents moisture and direct food contact with aluminum, in addition to preventing leakage;

- 5% aluminum: barrier to the entry of light and oxygen.

Due to the characteristics mentioned above and for being compact, Tetra Pak packaging, or carton packaging, is a great solution for food preservation, easy to be transported (due to the space and weight of this type of packaging), being the main choice of product manufacturers.

Has recycling

Despite being viable, the recycling of long-life packaging is difficult, as it has several pressed components that have different physical and chemical characteristics, which makes their separation difficult. However, according to the manufacturers, it can still be considered advantageous, because in the case of recycling the long-life milk carton packaging:

- The separation of its components produces 35% plastic/aluminum composite and 65% cellulosic fiber;

- A ton of carton packaging produces around 700 kg of paper (which would avoid cutting down 21 trees);

- Provides lower cost in production.

The recycling process takes place, first, in equipment that mixes the long-life packaging and water, strongly agitating the mixture for 30 minutes. During this period, the packaging paper fibers are separated from the plastic and aluminum layers and, therefore, mix with the water. Then, the paper fibers and water are submitted to a sieving process, which separates the two compounds and retains the plastic with the aluminum, allowing the pulp to go on to the paper reuse and manufacturing process. Meanwhile, the plastic and aluminum, still joined, are removed from the equipment and taken to other recycling companies that specialize in separating these two materials – in some cases, they are reused while still joined.

The fibers can be used to manufacture shoe insoles, paper towels, light packaging, corrugated cardboard, egg boxes, white paper and even return as a carton pack again. The plastic and aluminum composite is also being used for the production of various objects, such as the production of tiles, which are waterproof and resistant to bending.

According to the Business Commitment to Recycling Association (CEMPRE), there are 20 plants in Brazil specializing in the recycling of carton packs. The habit of recycling this type of packaging, however, is still not strong around here.

According to the company Datamark, which specializes in providing information on packaging industries, consumer goods and industrial inputs, in 2004 Brazil consumed around six million and five hundred thousand flexible packaging, including carton packs. However, the percentage of carton packaging destined for recycling was negligible: 16%. In 2008, this number rose to 26.6% and in 2011, 27.1% according to CEMPRE.

In addition to the packaging that comes in direct contact with food, the lid of the polypropylene plastic carton pack is also recycled.

Tips for discarding

It is important to discard clean recyclable materials so that diseases and odors do not proliferate, as well as to avoid contamination of recyclable items that are in the same place; because if contamination occurs, the recycling of contaminated materials becomes more difficult. Additionally, it makes sense to have the knowledge that these materials are often handled by people in cooperatives who practice the selection of objects. However, it is very difficult to remove the odor and traces of milk or other foods and beverages from the packages and bottles, which causes us to use a considerable amount of water, which is unreasonable due to its scarcity, and the use sounds irrational. of treated water, with high quality requirements to be potable, obtained at increasing costs, exclusively for this purpose.

According to the Municipal Department of Urban Cleaning (Limpurb), six tons of recyclable waste are not used daily because they are not clean and dry. To avoid this waste, check out some tips on how to wash your packaging with a lighter footprint:

- Enjoy the water during the dishwashing process;

- use a vegetable sponge

- Reuse the water that comes out of the washing machine.

The milk carton, being made from a mixture of materials with different properties, becomes quite dense, potentially causing environmental problems if improperly discarded, as it takes many years to be decomposed in nature. But, as the packaging of the milk carton is recyclable, be sure to dispose of it correctly. If you are in doubt about conscious disposal, in which of the categories: paper, plastic, metal, choose the first one, as it is the paper of the predominant material.